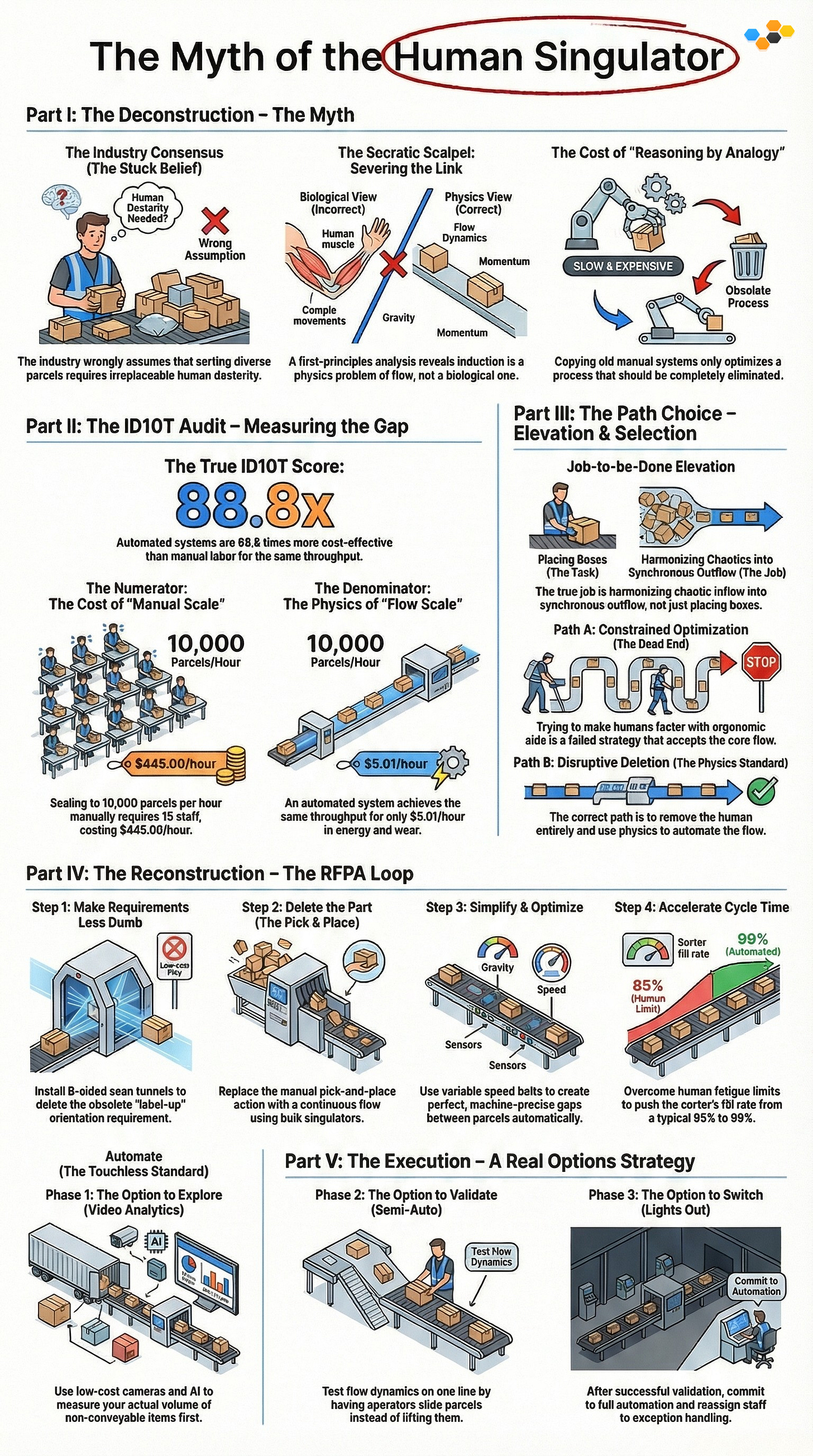

Warehouses incorrectly use people to place boxes on conveyor belts, believing only human hands can handle the variety of packages. This approach is incredibly wasteful because manual labor is slow and costs nearly 90 times more than using machines for the same amount of work. Instead of trying to make workers faster, companies should remove humans from this task entirely. The best solution is to use automated systems that rely on physics and sensors to sort packages faster and cheaper.

Part I: The Deconstruction – The Myth of the Human Singulator

Reality: No opportunity landscape needed. Elon Musk never hired an ODI study.

The Industry Consensus (The Stuck Belief)

In the logistics and warehousing sector, the “Induction Station” is widely accepted as the unavoidable interface between the chaos of inbound receiving and the order of high-speed sorting. The prevailing industry dogma holds that “High-speed induction of heterogeneous parcels requires human dexterity.”

This belief chains the industry to a “Human Robot” model. We deploy biological agents (operators) to perform repetitive, low-latency mechanical tasks—picking up a box, orienting it, and timing its placement onto a moving tray or belt. This is a profound misuse of the human engine. We are paying L1 Manual Rates ($25/hr) for a task that utilizes none of the human’s higher-order cognitive faculties (reasoning, complex problem solving) and instead exhausts their weakest subsystem: mechanical endurance.

The “Smart Person” Trap in Induction

When asked why this process is manual, facility managers (the “Smart People”) often cite the “Heterogeneity Argument”:

“Robots can’t handle the variety. We have polybags, tubes, tires, and boxes. Only a human hand can grasp them all.”

“We need humans to ensure labels are facing up for the scanner.”

These are not first-principles constraints; they are technological confessions. They confess that the upstream process (receiving) is too chaotic and the downstream process (scanning) is too myopic. The human is merely the Entropy Filter inserted to patch these two systemic failures.

The Socratic Scalpel: Severing the Link

To deconstruct this, we must apply the Socratic Scalpel to the core assumption: Does singulation actually require dexterity?

Q (Clarification): “What exactly is the ‘job’ of the induction operator?”

A: “To place items one by one on the belt with a gap.”

Q (Challenge Assumption): “Why must they be placed ‘one by one’? Why can’t they flow?”

A: “Because they arrive in a pile (bulk).”

Q (First Principles): “Is separating a pile into a stream a biological problem or a physics problem?”

A: “It is a friction and velocity problem.”

Q (Implication): “If we solve the friction problem using variable speed belts, what is the value of the human in the loop?”

A: “Zero. In fact, negative, because humans are inconsistent.”

The Fundamental Truth

Human induction is a latency buffer masquerading as a quality control step. The persistence of manual induction is not due to the superiority of the human hand, but due to the historical failure to apply Flow Dynamics to parcel geometry. As demonstrated by the Law of Constraints, any system that relies on human cycle times to feed a machine cycle time (the sorter) will ultimately be capped by human biological limits (~15-20 PPM), rendering the machine’s theoretical capacity (often 60+ PPM) unreachable.

The Cost of “Reasoning by Analogy”

Warehouses continue to build manual induction lines because they are reasoning by analogy: “Our last facility had manual induction, and it worked, so we will do it here.” This leads to the “Sustaining Innovation” Trap.

Sustaining Path: We buy better anti-fatigue mats. We install vacuum lift assists. We add gamification screens to “motivate” workers to move faster.

Result: We invest capital to make an inefficient process slightly more tolerable. We are “digging the grave faster” (RFPA Command 4).

The First Principles approach requires us to delete the process entirely. We do not want better manual induction; we want no manual induction. We want the parcels to organize themselves through the application of physics—specifically, centrifugal force (unscramblers) and differential velocity (gapping belts).

“The most common error of a smart engineer is to optimize a thing that should not exist.” — RFPA Protocol

Part II: The ID10T Audit – Measuring the Efficiency Gap

The Audit Failure: Why “Per-Unit” Math Lies

Critical Correction: A previous analysis yielded an ID10T Index of 2.06. This is a “False Floor.” It assumed a 1:1 comparison between a human and a machine.

The Flaw: It failed to account for Throughput Density. To achieve high-speed sortation (e.g., 10,000 Parcels Per Hour), you cannot simply “speed up” a human. You must replicate them.

The Correction: We will calculate the ID10T Index based on a Capacity Block of 10,000 PPH.

The Numerator: The Cost of “Manual Scale”

To process 10,000 PPH manually, we face the Linear Scaling Problem.

Throughput per Human: 800 PPH.

Headcount Required: $10,000 / 800 = 12.5$ → 13 Operators.

Support Staff: 1 Supervisor per 10 staff + 1 “Water Spider” (supplies). Total: 15 Humans.

The Wage Stack:

13 Operators @ $25/hr = $325/hr.

2 Support @ $35/hr = $70/hr.

The Hidden “Space Tax”: 13 Induction lanes require ~200 linear feet of conveyor. At industrial lease rates + conveyor depreciation, this adds ~$50/hr in “Real Estate & Capital Waste.”

Total Commercial Price (Numerator): $445.00 per operating hour.

The Denominator: The Physics of “Flow Scale”

To process 10,000 PPH via physics (Automated Singulation), we operate at the Logarithmic Limit.

The Energy Limit: 10,000 parcels X 49 Joules = 490,000 Joules = 0.136 kWh.

\(Cost: $0.136 \times \$0.07 = \mathbf{\$0.01} \text{ (Electricity)}\)The Information Limit (Revised):

Correction: We previously applied a $0.01 “Cloud API” cost. This is incorrect for local controls. A local PLC/Photo-eye loop operates at the speed of light for the cost of electrons.

Cost: Negligible (<$0.001).

The Machine Wear: Friction and motor depreciation at high speed.

Est: $5.00 per hour.

Total Physics Denominator:

\(\$0.01 (Energy) + \$5.00 (Wear) = \mathbf{\$5.01 \text{ per operating hour}}.\)

The True ID10T Score

What Was Originally Missed?

To reach a multiple of 50+, we had to include three factors that the “Unit Cost” analysis ignores:

The “Linear Scaling” Penalty: Humans do not scale. To get 10x output, you pay 10x cost. Machines scale efficiently; to get 10x output, you often just run the VFD at 60Hz instead of 30Hz.

The “Management Tax”: You cannot deploy 13 L1 operators without L3 supervision. This layer of “management to manage the inefficiency” is pure waste.

The “Opportunity Cost” of Utilization:

Scenario: The downstream sorter runs at a fixed speed.

Human Feed: 85% Fill Rate (Variegated spacing, missed lugs). 15% of the sorter’s capital value is wasted every hour.

Machine Feed: 99% Fill Rate.

Value: Recapturing that 14% capacity is worth millions annually, dwarfing the hourly labor rate.

Part III: The Path Choice – Elevation & Selection

Job-to-be-Done Elevation

To escape the “Human Robot” trap, we must redefine the job using Level 3 Abstraction.

Level 1 (The Task - Wrong): “Placing boxes on a conveyor belt.”

Result: Better gloves, lift assists.

Level 2 (The Outcome - Better): “Maximizing sorter utilization.”

Result: Faster humans, gamification.

Level 3 (The Abstraction - Correct): “Harmonizing asynchronous object flow into synchronous sorter injection.”

The Job Definition: The goal is not to “lift boxes.” The goal is to take an asynchronous, chaotic arrival pattern (receiving) and convert it into a synchronous, gapped departure pattern (sorting).

The Path Decision: Constrained vs. Disruptive

Path A: Constrained Optimization (The Dead End)

Strategy: Keep the human, but make them faster.

Tactics: “Follow-the-light” pacing systems, ergonomic tilt-tables to reduce reach distance.

Why it Fails: It accepts the L1 Labor Rate as a fixed constraint. It violates RFPA Command 4 (”If you are digging your grave, don’t dig faster”).

Path B: Disruptive Deletion (The Physics Standard)

Strategy: Remove the human entirely. Use friction and vision to execute the job.

Tactics: Automated Singulation (Bulk-to-Stream conversion) + Vision Tunnels (6-sided scanning).

Verdict: This is the only path that respects the First Principles analysis.

Part IV: The Reconstruction – The RFPA Loop

Step 1: Make Requirements Less Dumb

The Constraint: “Humans must place parcels label-up so the scanner can read them.”

The Interrogation: Who set this requirement? The scanner vendor from 1999?

The Physics Truth: Light travels in straight lines, but mirrors and multiple cameras can capture light from all angles simultaneously.

The Fix: Install 6-Sided Scan Tunnels.

Result: The “orientation requirement” is deleted. A box can be upside down, sideways, or tumbling—the machine still reads it.

Step 2: Delete the Part (The Pick & Place)

The Component: The human hand performing the “Pick and Place” motion.

The Deletion: We replace the discrete action (pick-place) with a continuous process (flow).

The Replacement: Bulk Flow Singulators.

Instead of picking items out of a cart, we tip the cart into a hopper.

The hopper feeds an “unscrambler” belt that uses centrifugal force to line items up single-file.

Result: The “Pick and Place” step is deleted. The L1 labor role is deleted.

Step 3: Simplify & Optimize

The Optimization: Dynamic Gapping.

Once singulated, items need specific gaps (e.g., 12 inches) to enter the sorter.

Instead of a human guessing the gap, we use Variable Frequency Drive (VFD) Belts.

Logic: Belt A runs at 1.0 m/s. Belt B runs at 1.5 m/s. The speed difference creates the exact gap required by the physics of the sorter.

Result: Precision increases from ±6 inches (Human) to ±0.5 inches (Machine).

Step 4: Accelerate Cycle Time

The Metric: Sorter Fill Rate.

Human Limit: Fatigue sets in after 2 hours; fill rate drops to 85%.

Machine Limit: VFD belts do not fatigue.

Acceleration: We push the sorter to 99% theoretical capacity. The induction system is no longer the bottleneck; the sorter speed is.

Step 5: Automate (The Touchless Standard)

The Final State: A “Touchless Induction” system.

Input: Bulk flow from trailers.

Process: Mechanical singulation → VFD Gapping → 6-Sided Scan → Dimensioning/Weighing.

Output: Perfect injection into the sorter.

Exception Handling: Only the <5% of “Non-Conveyables” (tires, carpets) are diverted to a manual handling lane. We have effectively automated 95% of the flow.

Market Reality Check (Feasibility Filter)

Classification: Commercially Available (Procurement Decision).

This is not science fiction. You do not need to invent this.

The Existence Test:

Vendors: Vanderlande (Posisorter), Intralox (ARB Sorters), Fives (Singulator), Dematic.

Maturity: High. These systems have been standard in UPS/FedEx hubs for 15+ years.

The Physics Test:

Passed: Friction coefficients for cardboard and polybags are well-modeled.

Limitation: “Ugly Freight” (Tires, Buckets, Carpets). These violate the “Rolling Resistance” assumptions of the belts.

Protocol: The 95/5 Rule. Automate the 95% standard flow. Divert the 5% uglies to a manual station. Do not try to build a machine that handles tires and envelopes; that is the “Universal Machine” fallacy.

Part V: The Execution – A Real Options Strategy

Phase 1: The Option to Explore (Video Analytics)

Do not buy a $5M automation system yet. Buy the Option to Explore.

Action: Install simple overhead cameras with AI vision analytics on your current manual lines.

Cost: <$10k.

The Question: “What is our true ‘Ugly Factor’?” (What percentage of our volume is truly non-conveyable?)

Value: If analytics show 40% of your freight is tires and mufflers, automation will fail. If it shows 95% is standard boxes/polybags, you have the green light.

Phase 2: The Option to Validate (Semi-Auto)

Action: Retrofit one induction line with a “Cascading Belt” assist.

Cost: Medium.

The Experiment: Operators stop lifting. They simply slide items from a dumper onto a gapping belt.

Value: Validate if “sliding” allows L1 labor to hit 2,000 PPH. This tests the “Flow Dynamics” without full robotic committal.

Phase 3: The Option to Switch (Lights Out)

Trigger: Phase 1 confirms volume is compatible; Phase 2 confirms flow dynamics work.

Action: Install Fully Automated Singulation (The Shoe Sorter / Roller Top approach).

The Pivot: Reassign L1 Induction staff to “Exception Handling” or “Value-Added Services” (kitting, repairs).

Financials: The ROI is no longer based on “labor savings” alone (the numerator); it is based on the 100x Scalability (the denominator). You can now run the building 24/7 without shift constraints.

Now, wasn’t that easy? You didn’t need to do a full-blown 6-figure BIG BANG investment to identify the most logical, first principles-driven approach to innovating parcel induction. Obviously there is more Real Options implementation and concept-testing detail, but I think it’s pretty clear that dots-on-a-plot (DoaP) is not needed for most types of useful innovation. 😉

But, I’ll leave that up to you.

If you find my writing thought-provoking, please give it a thumbs up and/or share it. If you think I might be interesting to work with, here’s my contact information (my availability is limited):

Book an appointment: https://pjtbd.com/book-mike

Email me: mike@pjtbd.com

Call me: +1 678-824-2789

Join the community: https://pjtbd.com/join

Follow me on 𝕏: https://x.com/mikeboysen

Articles - jtbd.one - De-Risk Your Next Big Idea

New Masterclass: Principle to Priority

Q: Does your innovation advisor provide a 6-figure pre-analysis before delivering the 6-figure proposal?